21, Jalan MJ 14,

Taman Industri Meranti Jaya,

47100 Puchong,

Selangor, Malaysia.

+603-8066 2496

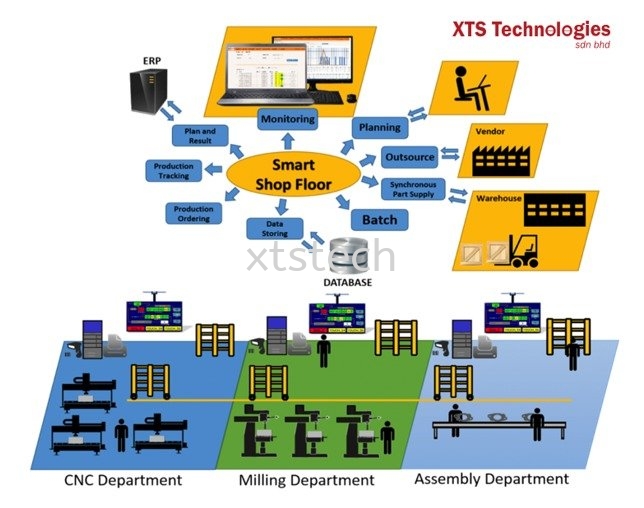

In Industrie 4.0, it will be possible to order manufacturing processes and capacities at the click of a mouse, similar to music streaming. In manufacturing as a service, the performance of the machine is paid for. In the future, this will also hold true for individual production elements – robots for example. It will not be the machine itself that is purchased, but its output.

Industrie 4.0 and the Internet of Things will also affect the machines themselves. They will become increasingly sensitive, more autonomous, more mobile and easier to operate. Soon, robots will be intelligent enough to understand our language and gestures. They are increasingly evolving into assistants in factories, supporting humans in their work. Because a robot is better at certain things – such as precision and speed – it provides humans with entirely new capabilities.

Pile Turner Toppy Advance is an electrically powered pile turner that allows to remove the pallet of paper from the printing machine and turn it for the second side of printing.

This kind of mobile pile turner can handle pallets of paper up to a maximum weight of 1000 kg, and with size from 50 x 70 cm to 76 x 106 cm.

Toppy Advance Pile Turner is available in a wide-base (straddle type) configuration for closed-bottom pallets.

|

Please contact XTS (SEA) South East Asia from Malaysia, Indonesia, Singapore, Thailand, Philippines, Vietnam, Laos, Myanmar, Cambodia, Brunei at : sales@xtstech.com |

The Roll Turner Aspo 600 allows to lift and turn reels of different type of material, up to a maximum weight of 600 Kg.

The function of this machine is to rotate a reel from vertical to horizontal position and vice versa. It can be provided with some optional like the label clamp, that has been conceived to avoid the effect cone.

#xtstechnologies #xtstech #logisticsolutions #rollturner